|

Listen to this article  |

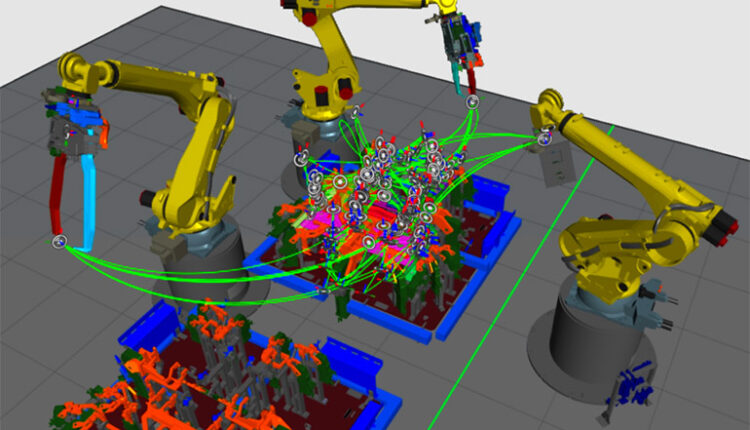

Valiant TMS is integrating robot motion optimization as a service. Source: Realtime Robotics

Realtime Robotics today announced that Valiant TMS will integrate its Optimization-as-a-Service offering with customers’ manufacturing operations. The companies said the combination of Realtime’s proprietary software and engineering expertise with Valiant TMS’s manufacturing industry experience will improve the efficiency and productivity of automated operations.

With Optimization-as-a-Service, companies can identify and eliminate production bottlenecks, significantly reducing cycle time and programming time, said Realtime Robotics.

“Manufacturers are always looking for ways to improve their production processes, but few have the time or resources to spend on such a lengthy, involved task,” said Peter Howard, CEO of Realtime Robotics, in a release.

“We’re thrilled that our optimization solution has struck a chord with so many, automating the task of generating and testing potential layouts and paths to quickly present them with the optimized solution,” he said. “They can reap the benefits without wasting hours of their team’s time.”

Boston-based Realtime Robotics claimed to be a leading provider of automatic, collision-free motion planning for industrial robots. The company said its technology generates optimized motion plans and interlocks to shorten cycle times in multi-robot cells.

Realtime Robotics quickly finds paths

Realtime Robotics said its systems empower robots to function together in unstructured and collaborative workspaces, reacting to dynamic obstacles the instant changes are perceived. It added that its technology rapidly generates and tests hundreds of thousands of potential robot paths, determining the best motion sequences based on target sequences, robot reach, and other customer-desired parameters.

To begin, a user needs only a simulation file or a digital twin of the workcell to be improved. Realtime Robotics asserted that a manufacturer can go through the entire optimization process without causing any delays in current production.

Once the analysis is complete and the results validated, the newly optimized plan can be transferred to the factory floor and put into use without delay, it said.

In a recently completed multi-robot application, Valiant TMS used Realtime Robotics’ optimization offering to design motion plans with more efficient paths, better interlocks, and a faster execution time. It ultimately reduced a customer’s robot cycle time by 17% and cut robot programming time in half.

“I am impressed by the results provided by Realtime Robotics. It seems to be the best software among all on the market,” said Pawel Kukowa, simulation engineer at Valiant TMS. “Everything indicates that, after some improvements, it will be able to eliminate manual work during robot path creation.”

Valiant TMS seven-robot automotive framing application. Source: Realtime Robotics

Valiant TMS finds a ‘game changer’

“Our collaboration with Realtime Robotics is very interesting and trendsetting,” said Michael Schaubmayr, group manager for mechanical engineering simulation at Valiant TMS.

“The proofed cycle time-reduction of 17% in comparison with manual programming is breathtaking and will be a game-changer in automation,” he said.

Founded in 1959, Valiant TMS is an Industry 4.0 systems integrator that specializes in welding and joining, automated assembly and test, industrial parts washers, and final assembly systems. The Windsor, Ontario-based company has 1,500 team members in 20 facilities in 11 countries.

Credit: Source link

Comments are closed.