|

Listen to this article  |

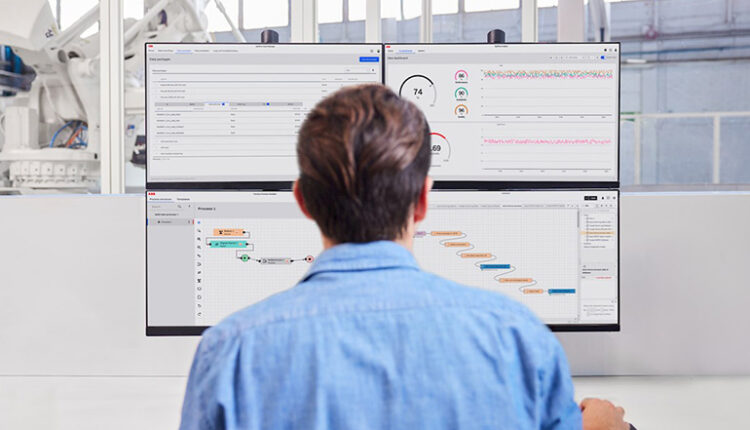

ABB Robotics released its new modular OptiFact software platform, which streamlines data collection, visualization, and analysis in automated production facilities. The platform enables users to collect, manage, and analyze data from hundreds of factory devices, including ABB robots, to determine key performance indicators including cycle time and overall equipment efficiency (OEE). By speeding up diagnostics and decision-making, OptiFact increases the production line uptime with less engineering effort, ensuring production can keep pace with customer demand.

“Across industries, we see a dramatic increase in the digitalization of manufacturing as companies seek to increase the flexibility, efficiency, and sustainability of their operations in the face of changing consumer behaviors and long-term global skilled labor shortages,” Marc Segura, President of ABB Robotics, said. “At ABB Robotics, we are enabling this shift with software products that businesses need to accelerate their growth in today’s fast-changing market.”

Digitization, the acceleration of sustainable manufacturing, and the pandemic have all contributed to the increased demand for automation solutions. According to the International Federation of Robotics (IFR), the number of robots sold worldwide has almost tripled over the past decade. Growing reliance on automation has resulted in increasingly complex production environments, driving demand for tools to enable plant managers to collect and capitalize on data gathered as a side product of automation.

Imagine, realize, elevate

OptiFact adds to ABB’s comprehensive suite of leading digital solutions that help businesses of all sizes imagine new digitally enabled processes, realize them on the factory floor, and elevate operations by simplifying production to increase productivity and flexibility. With OptiFact, factory operators can determine the root cause of production errors and use ABB’s RobotStudio Cloud to make adjustments to the program and develop an improved robotic solution.

RobotStudio’s desktop, cloud, and AR viewer solutions help users easily plan and imagine new deployments of ABB industrial robots or adapt existing ones to new production tasks. Its innovative features such as Automatic Path Planning allow robots to determine the most efficient paths and avoid collisions with existing obstacles. Offering a true “what you see is what you get” user experience with 99% accuracy between the robot’s digital twin and its real-world deployment, RobotStudio speeds design and commissioning time by up to 50%.

Application-specific AI-driven software technology such as ABB’s Item Picker offers value-added features that facilitate the realization of robotics deployments with enhanced performance, safety, and quality. Best-in-class motion control cuts the power requirements of pick and place operations by up to 17%, speeding tasks by 13%. VSLAM technology (visual simultaneous localization and mapping) leverages artificial intelligence for accurate indoor navigation in dynamic indoor environments.

Register now so that you don’t miss this exciting event.

Register now so that you don’t miss this exciting event.

Performance in multiple production environments

OptiFact has been deployed in several production facilities, including a highly automated automotive production environment, where it collects and analyzes production process cycle times and other key performance indicators, providing unparalleled visibility into factory operations and saving up to 25% of experts’ time. As a result, the customer has added the deployment of over 580 robots in its operations.

The platform has also proven its value for small and mid-sized enterprises. An additional pilot demonstrated the platform’s ability to identify production bottlenecks in production lines involving up to 20 robots. The customer’s digital team integrated OptiFact into its production environment in just two months from first contact to final delivery. Once deployed, OptiFact simplified data collection and the visualization of key performance indicators such as cycle time and Programmable Logic Controller (PLC) alarms. By addressing operational inefficiencies detected using OptiFact, the facility increased production time by up to 20%.

Credit: Source link

Comments are closed.