|

Listen to this article  |

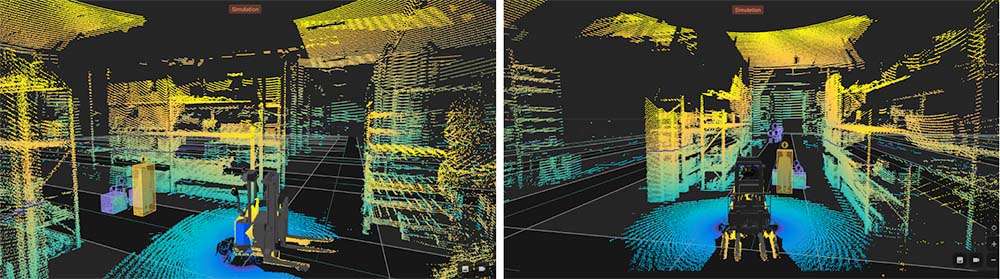

The simulation environment from Applied Intuition enables accurate modeling of the facility as well as the AMR behaviors. | Imade credit: Applied Intuition

Autonomous mobile robot (AMR) provider Seegrid and simulation software provider Applied Intuition have partnered to advance the use of simulation tools to accelerate AMR projects and customer deployment use cases.

It’s no secret in the AMR industry that the process of specifying a fleet size and characterizing a customer’s application is a highly complex process. In the early days of the industry, AMR sales and applications engineering staff made use of complex spreadsheets, combined with time and path estimations, to determine the applicability of AMRs in new application settings.

In most cases, the real application understanding didn’t come until actual AMRs were deployed into the customer’s facility in a pilot project. The state of the art for application fleet sizing and application characterization is continually evolving.

Simulation entered the picture a couple of years ago, and many vendors built their own simulation environments from scratch. Independently, Amazon Web Services and the Amazon Robotics group have developed and marketing tools such as AWS Robomaker. However, AWS Robomaker is a currently a tool for roboticists and isn’t a great option for AMR end-users.

By partnering with a leading software simulation provider, Seegrid is looking to accelerate the capabilities of simulated work environments and more closely predict real world outcomes.

The partnership involves a significant investment by Seegrid and will enable Seegrid to quickly validate product innovations in more environments and use cases across the supply chain than feasible with manual testing. The software developed by Applied Intuition delivers high-fidelity simulation modeling that will help the Seegrid sales and applications team to accelerate the sales cycle and deliver better outcomes for its clients.

Applied Intuition can provide photo realistic simulations of the world. | Image credit: Applied Intuition

“Applied Intuition’s platform simulates a wide range of environments, layering in different conditions to safely pressure test next generation ideas in autonomous vehicle technology,” said Peter Ludwig, CTO and co-founder of Applied Intuition. “Manufacturing and distribution facilities are a complex, highly dynamic operational design domain – we’re thrilled to collaborate with industry leader Seegrid to help enable the rapid acceleration of the growing AMR market.”

“Consumer demand and a shrinking labor force are putting pressure on nearly every industry, and in turn, putting pressure on AMRs to effectively and consistently interpret and respond to ever-changing situations,” said Jim Rock, Seegrid’s CEO. “Our customers rely on Seegrid to deliver industry leading automation solutions that can safely ensure productivity – highly advanced simulation during ideation, test, and development speeds up our ability to deliver next generation AMRs best equipped to address the unpredictable events in facility workflows.”

Not only does simulation shorten the sales cycle, but it also enables Seegrid to test new use cases for AMRs and to also improve its software and to validate that a software fix solves a given problem.

In May 2021, Seegrid announced the formation of its Blue Labs. “Blue Lab’s team of talented researchers anticipate quickly revealing additional pathways to transform material handling for incorporation into Seegrid AMR and software solutions,” said Todd Graves, Chief Technology Officer (CTO) for Seegrid. “With a team of the best innovators in mobile automation, we have the vision, ambition, and expertise to make our customers even more competitive in their ability to meet demand.”

Simulation is one area of engineering that many AMR companies are racing to develop as quality simulation is becoming an necessary engineering, sales and support tool.

This image show LiDAR simulation of the Seegrid Palion AMR. | Image credit: Applied Intuition

Development Use Cases

Seegrid builds multiple autonomous mobile robots (AMRs) including Palion Lift, Palion Pallet Truck, and Palion Tow Tractor. Seegrid will leverage Applied’s testing tools, Simian, Spectral, Orbis, and Meridian, to test its AMR products in virtual environments. Applied’s testing software platform will enable Seegrid to quickly validate product innovations in more environments and use cases across the supply chain than feasible with manual testing.

The two companies are focusing on the following development use cases.

- Sensor placement: Spectral will help Seegrid test the virtual placement, evaluation, and iteration of various sensor layouts on future Palion AMRs. Spectral’s simulated sensors are accurately modeled in collaboration with the sensor providers, and have been refined with physical evaluation of real world sensor data to cover any unexpected anomalies.

- Multi-robot autonomy validation: Applied’s software tools provide critical validation testing and workflows for Palion AMRs. The tools allow Seegrid engineers to create scenarios and turn them into test cases with pass/fail evaluation criteria, and run scenario tests with tens or even hundreds of robots. Other simulation tools in the market tend to focus on sensor data generation for experimentation and model training while they fall short on production-grade validation testing and workflows.

- Articulated robot control: Palion AMRs must safely interact with objects in highly dynamic environments they operate in. For example, they must correctly detect pallets and lift, haul, or place them onto various surfaces. Applied’s simulation platform allows Seegrid to accurately simulate robot articulation and manipulation as part of the company’s extensive testing process

Credit: Source link

Comments are closed.